Low Noise Transmission Belt

3rd April 2025

At a recent event, Megadyne showcased their new Quiet, Self-Tracking (QST) System— an alternative to traditional straight tooth profiles offering efficient conveying.

Engineered to address the critical challenges faced by manufacturers and operations managers in logistics and material handling operations, the QST System delivers improved noise reduction, more compact transmission, energy efficiency, and operational reliability.

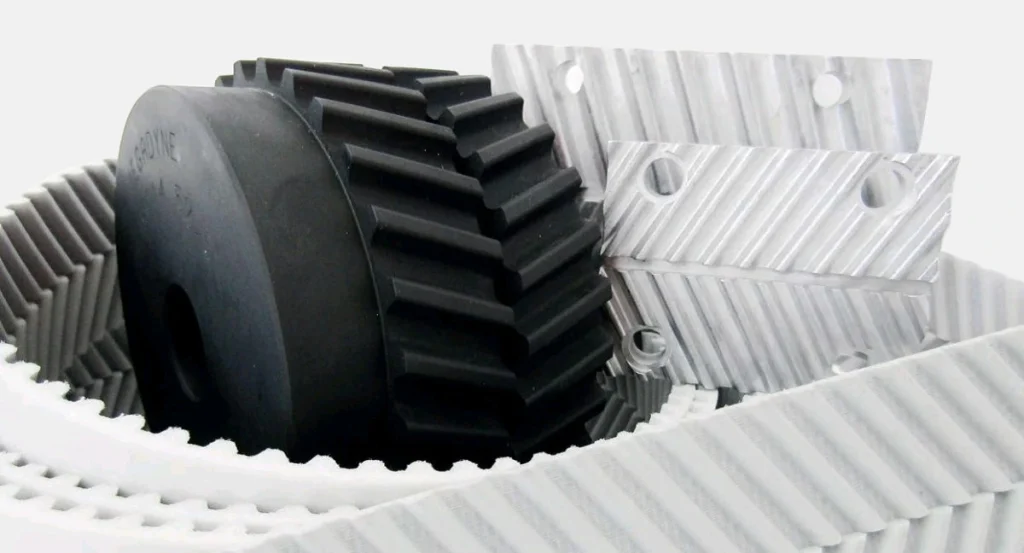

QST profile VS Standard straight tooth profile

Luca Zironda, Global ISM Material Handling & Automation Power Transmission Expert at Megadyne, explains, “Traditional systems with standard straight tooth profiles often come with compromises: persistent noise, energy inefficiencies, and tracking requirements. The QST System addresses these challenges directly, offering a quieter, more efficient solution.”

“One of the standout features of the Megadyne QST system,” Luca explains, “is its advanced tooth design, which optimises power transmission”, enabling, “a more compact transmission while minimising energy loss.”

By reducing vibrations and noise levels, the system creates significantly quieter and more efficient operations, not only enhancing the working environment but also leading to reduced energy consumption, directly impacting both the bottom line and sustainability goals.

Benefits for the workforce: a quieter, safer environment

Megadyne claim drastically reduced sound levels improving the impact of noise on workers’ well-being, creating a more comfortable and less disruptive environment. They believe that the reduction may even be so significant that ear protection could become unnecessary even with high-speed high-load intralogistics applications.

Operational benefits: reduced downtime and maintenance time

The new system has a self-tracking and low-maintenance design to which Megadyne claim eliminates the need for constant adjustments and frequent repairs, leading to long-term savings, with less wear on the belts, extended service life, and fewer inspections. The result to which would be reduced downtime, more reliable operations, and significant maintenance cost reductions.

Business benefits: lowering energy costs and waste

From a business perspective, the reduction in conveyor energy consumption provided by the Megadyne QST system is said to be transformative. By operating more efficiently, this system helps businesses cut down on their energy costs while simultaneously reducing their carbon footprint. This results in more sustainable operations, aligning with modern industrial demands for performance and environmental responsibility.

Commitment to efficiency

“The Megadyne QST system exemplifies how innovation can drive operational improvement across multiple levels,” says Luca Zironda. “From reducing noise and energy consumption to enhancing operational efficiency and lowering maintenance costs, the Megadyne QST system transforms how logistics businesses operate.”

Read Similar…

[Podcast] Adapting to Industry 4.0: Intralogistics Automation